Kopp3D Machines

Sale of machines

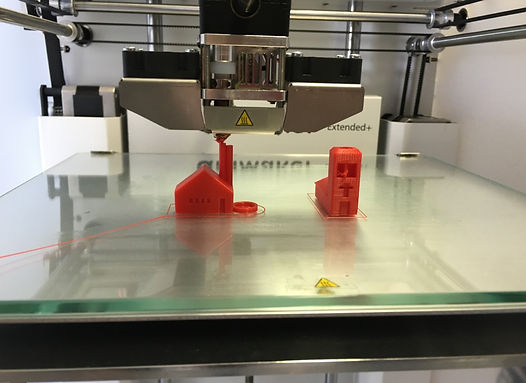

3D Printing Machines

The choices available in the 3D printer market can be overwhelming. Our hardware experts analyze multiple factors before suggesting suitable machines that meet your requirements.

Our approach and process depend on the technology qualification (FFF, SLA, SLS, MJF, and DMLS).

Choose right

Applications

This is the first step in choosing the right hardware. Industries could be aerospace, automotive, architecture, engineering, jewelry, medical, and dental.

Functional parts or visually attractive? Prototypes or models? One-off part or production volumes?

What we use

Materials

Machines and their workflow have different material compatibility and processes. Thus, materials are a key aspect in part and technology qualification. Some of the available materials are:

Polymers- PA12, PA6, ABS, PLA, PP, PC, TPU, Carbon fiber, Clear, Dental resins, Jewelry resins, etc.

Metals- Aluminium, Stainless Steel, Tool Steel, Titanium, Nickel Alloys, Cobalt Chrome, etc.

Polymers or metals? Single or multiple material printing at the same time? Open system? Certified materials?

Build Volume

Each machine has a maximum printing area. The building envelope determines the biggest part dimensions a machine can produce. The typical volume is 200x200x200 mm.

Smallest and largest dimension? 50mm? 500mm? Slicing the larger parts into smaller ones? Batch printing?

Print quality and speed

The print quality and print speed are usually inversely proportional. The layer height determines the surface finish and smoothness.

Surface finish? Project timelines? 20 or 200 microns? 50 or 150mm/s?

Software

Software is an essential tool right from the design stage to the actual printing. Different stages employ different tools such as design, build preparation, and process monitoring.

CAD? Licenses? File formats? Profiles and material parameters? DfAM?